|

| January 11, 2022 | Volume 18 Issue 02 |

Materials News & Products

Designfax weekly eMagazine

Archives

Partners

Manufacturing Center

Product Spotlight

Modern Applications News

Metalworking Ideas For

Today's Job Shops

Tooling and Production

Strategies for large

metalworking plants

Weird stuff: Moon dust simulant for 3D printing

Crafted from a lunar regolith simulant, Basalt Moon Dust Filamet™ (not a typo) available from The Virtual Foundry closely mirrors the makeup of lunar regolith found in mare regions of the Moon. It enables users with standard fused filament fabrication (FFF) 3D printers to print with unparalleled realism. Try out your ideas before you go for that big space contract, or help your kid get an A on that special science project.

Crafted from a lunar regolith simulant, Basalt Moon Dust Filamet™ (not a typo) available from The Virtual Foundry closely mirrors the makeup of lunar regolith found in mare regions of the Moon. It enables users with standard fused filament fabrication (FFF) 3D printers to print with unparalleled realism. Try out your ideas before you go for that big space contract, or help your kid get an A on that special science project.

Learn more.

Make nylon 3D-printed prototypes and parts in the office

The new SLS 300 from 3D Systems is an affordable, turnkey, closed-loop 3D-printing system designed to operate in a smaller-footprint environment. SLS 300 makes selective laser sintering available to a broader range of customers with a high-reliability, affordable solution to produce end-use parts. Users can produce tough, durable parts from a range of production-grade nylon materials. Amazing fill, finishing, and clean-up systems.

The new SLS 300 from 3D Systems is an affordable, turnkey, closed-loop 3D-printing system designed to operate in a smaller-footprint environment. SLS 300 makes selective laser sintering available to a broader range of customers with a high-reliability, affordable solution to produce end-use parts. Users can produce tough, durable parts from a range of production-grade nylon materials. Amazing fill, finishing, and clean-up systems.

Learn more.

Will it erode? 3D-printing materials comparison from Xometry

Which 3D-printed plastics are the toughest? In this "Will it ..." video, Greg Paulsen, Xometry's Director of Application Engineering, 3D printed Benchies (3D test models) using different materials (such as polycarbonate, PLA, polypropylene, ULTEM, and Nylon 11 and 12) and processes (such as FDM, SLS, MJF, SLA, LSPc, Polyjet, and DLS) and then ran several abrasion tests on them. Watch to find out which 3D-printed plastic is truly the toughest of them all!

Which 3D-printed plastics are the toughest? In this "Will it ..." video, Greg Paulsen, Xometry's Director of Application Engineering, 3D printed Benchies (3D test models) using different materials (such as polycarbonate, PLA, polypropylene, ULTEM, and Nylon 11 and 12) and processes (such as FDM, SLS, MJF, SLA, LSPc, Polyjet, and DLS) and then ran several abrasion tests on them. Watch to find out which 3D-printed plastic is truly the toughest of them all!

View Part 1.

View Part 2.

Graphene Handbook: Learn all about this wonder material

Metalgrass LTD has published the 11th edition of its "Graphene Handbook," a comprehensive resource on graphene technology, the industry, and the market for this wonder material made of single layers of atoms of pure carbon. The book includes development history, production methods, current research, an intro to metrology and standardization, and even an investment guide. Under 100 bucks for digital edition. Hard copy available too.

Metalgrass LTD has published the 11th edition of its "Graphene Handbook," a comprehensive resource on graphene technology, the industry, and the market for this wonder material made of single layers of atoms of pure carbon. The book includes development history, production methods, current research, an intro to metrology and standardization, and even an investment guide. Under 100 bucks for digital edition. Hard copy available too.

Learn more.

Who knew? How colorants affect plastic

In plastic injection molding, one aspect of polymer characteristics that doesn't always get the consideration it deserves is the addition of colorant. Believe it or not, there is a whole scientific body of knowledge about the ways in which adding color to plastic can affect its behavioral properties. This short article by Denny Scher of ICO Mold takes a high-level look at some of the different, and surprising, ways colorants can affect plastics.

In plastic injection molding, one aspect of polymer characteristics that doesn't always get the consideration it deserves is the addition of colorant. Believe it or not, there is a whole scientific body of knowledge about the ways in which adding color to plastic can affect its behavioral properties. This short article by Denny Scher of ICO Mold takes a high-level look at some of the different, and surprising, ways colorants can affect plastics.

Read the full article.

Retaining magnets from JW Winco: Universal and clever

JW Winco has expanded its magnet line to support more applications with new materials, shapes, systems, and even raw magnets. Learn about their latest offerings, including retaining magnets designed for corrosive environments (GN 50.8), encapsulated magnets designed for sensitive or painted surfaces (GN 51.8), handle magnets (GN 53.3), and powerful magnets designed to handle challenging environs (GN 52.6).

JW Winco has expanded its magnet line to support more applications with new materials, shapes, systems, and even raw magnets. Learn about their latest offerings, including retaining magnets designed for corrosive environments (GN 50.8), encapsulated magnets designed for sensitive or painted surfaces (GN 51.8), handle magnets (GN 53.3), and powerful magnets designed to handle challenging environs (GN 52.6).

Learn more.

3D print tool steel with the ease of a plastic

The Virtual Foundry, a pioneer in advanced 3D-printing materials, is excited to announce the launch of their latest innovation: M300 Tool Steel Filamet™ (not a typo). This material answers the demand for FFF 3D-printable Tool Steel, delivering unparalleled strength and versatility. What sets this material apart is its seamless compatibility with various 3D printers, including Creality, Bambu Lab, Ultimaker, and more. The filament prints effortlessly, resembling the ease of working with PLA (plastic).

The Virtual Foundry, a pioneer in advanced 3D-printing materials, is excited to announce the launch of their latest innovation: M300 Tool Steel Filamet™ (not a typo). This material answers the demand for FFF 3D-printable Tool Steel, delivering unparalleled strength and versatility. What sets this material apart is its seamless compatibility with various 3D printers, including Creality, Bambu Lab, Ultimaker, and more. The filament prints effortlessly, resembling the ease of working with PLA (plastic).

Learn more.

Great Resources: Sheet metal design guide

If you're looking for a basic guide to sheet metal design, this one from Xometry will serve your needs well. Follow the design requirements and tolerances in this guide to ensure parts fall closer to design intent. This is the type of information you'll sock away and then refer to again and again.

If you're looking for a basic guide to sheet metal design, this one from Xometry will serve your needs well. Follow the design requirements and tolerances in this guide to ensure parts fall closer to design intent. This is the type of information you'll sock away and then refer to again and again.

Read the full article.

Particle foam perfectly distributed thanks to simulation with Ultrasim

BASF's Ultrasim simulation solution now includes Infinergy, an expanded thermoplastic polyurethane (E-TPU) that is used in a wide range of applications to make components with particle foam -- from bicycle tires to the soles on shoes. Identify and solve problems related to pneumatic filling when distributing particle foams in molds, even taking gravity and mold closing into consideration. Avoid those pesky air pockets.

BASF's Ultrasim simulation solution now includes Infinergy, an expanded thermoplastic polyurethane (E-TPU) that is used in a wide range of applications to make components with particle foam -- from bicycle tires to the soles on shoes. Identify and solve problems related to pneumatic filling when distributing particle foams in molds, even taking gravity and mold closing into consideration. Avoid those pesky air pockets.

Learn more.

Premium polymer DLP printer is half the price of its predecessor

Desktop Metal has just launched the ETEC Pro XL -- a premium polymer digital light processing (DLP) printer that enters the market at less than half the price as its predecessor. DLP is regarded by many as a superior polymer 3D-printing technology for speed, surface finish, and accuracy. Ideal for automotive and machine parts, aerospace components, housings, connectors, jigs and fixtures, short-run molds, and more.

Desktop Metal has just launched the ETEC Pro XL -- a premium polymer digital light processing (DLP) printer that enters the market at less than half the price as its predecessor. DLP is regarded by many as a superior polymer 3D-printing technology for speed, surface finish, and accuracy. Ideal for automotive and machine parts, aerospace components, housings, connectors, jigs and fixtures, short-run molds, and more.

Read the full article.

CNC machining case study: One-of-a-kind computer chassis

Learn how Josh Sniffen, the YouTuber behind the popular PC-building channel "Not From Concentrate," trusted Xometry to provide a wide range of manufacturing options, personalized Design for Manufacturing (DFM) feedback, and order management support for his latest creation: the HEXO ATX computer chassis. All in all, Sniffen procured parts using Xometry's CNC machining service, selective laser sintering 3D-printing service, and sheet metal cutting and fabrication services. A neat insider look at the process.

Learn how Josh Sniffen, the YouTuber behind the popular PC-building channel "Not From Concentrate," trusted Xometry to provide a wide range of manufacturing options, personalized Design for Manufacturing (DFM) feedback, and order management support for his latest creation: the HEXO ATX computer chassis. All in all, Sniffen procured parts using Xometry's CNC machining service, selective laser sintering 3D-printing service, and sheet metal cutting and fabrication services. A neat insider look at the process.

Read this Xometry case study.

Which parts should be 3D printed? AI combs through CAD files to find out

One of the biggest challenges in transitioning to additive manufacturing (AM) is the ability to identify which parts are best suited for the process quickly and easily. Learn how Danfoss, Stanley Engineered Fastening, and even the U.S. military have utilized advanced additive manufacturing software to automate the process, reducing material waste and energy costs, improving part reliability, decreasing lead times, as well as now having the ability to identify part consolidation opportunities through intelligent AM decision-making.

One of the biggest challenges in transitioning to additive manufacturing (AM) is the ability to identify which parts are best suited for the process quickly and easily. Learn how Danfoss, Stanley Engineered Fastening, and even the U.S. military have utilized advanced additive manufacturing software to automate the process, reducing material waste and energy costs, improving part reliability, decreasing lead times, as well as now having the ability to identify part consolidation opportunities through intelligent AM decision-making.

Read the full article.

9 key design tips for injection molding

Keep costs down and quality up all while optimizing your injection molded designs with these helpful tips from Xometry. Learn how to build better injection molded parts and products -- using draft angles, ribs and gussets, radii, fillets, and more -- and set expectations for the injection molding process. Good info here.

Keep costs down and quality up all while optimizing your injection molded designs with these helpful tips from Xometry. Learn how to build better injection molded parts and products -- using draft angles, ribs and gussets, radii, fillets, and more -- and set expectations for the injection molding process. Good info here.

View the video.

Metal additive manufacturing: Rocket turbopump design

Mixing undergraduate curiosity and real-world engagement, two students from Colorado University Boulder Aerospace Engineering Sciences program, Zachary Lesan and Patrick Watson, started an independent effort on turbopump design and manufacture that is a lesson in determination and industry collaboration. With lots of supplies and advice from industry heavy hitters including Velo3D, CFturbo, SpaceX, and many more, their project has reinforced significant points being made about next-generation rocketry.

Mixing undergraduate curiosity and real-world engagement, two students from Colorado University Boulder Aerospace Engineering Sciences program, Zachary Lesan and Patrick Watson, started an independent effort on turbopump design and manufacture that is a lesson in determination and industry collaboration. With lots of supplies and advice from industry heavy hitters including Velo3D, CFturbo, SpaceX, and many more, their project has reinforced significant points being made about next-generation rocketry.

Read the full article.

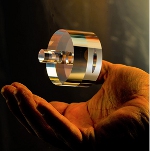

Transparent ceramics for extreme optics

Sapphire is an inherently transparent ceramic material that is resistant to extremes of temperature and environment. Sapphire can be processed to unique and precise shape/form by diamond grinding and polishing to allow full transparency. INSACO is a global leader in this capability -- and working with ultra-hard materials in general.

Sapphire is an inherently transparent ceramic material that is resistant to extremes of temperature and environment. Sapphire can be processed to unique and precise shape/form by diamond grinding and polishing to allow full transparency. INSACO is a global leader in this capability -- and working with ultra-hard materials in general.

Learn more.

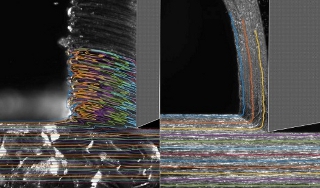

Gummy metals cut better when marked with Sharpie or glue -- researchers figuring out why

It was back in 2018 that researchers from Purdue University first announced results of their deep dive into finding ways to make gummy metals such as aluminum, stainless steels, nickel, copper, and tantalum easier to cut. They found that first marking the metals with certain common substances -- like a Sharpie marker or glue -- can make big improvements. Now they are figuring out why.

Their ongoing research and its results may help in manufacturing products and reducing component failures.

The application of a permanent marker, glue, or adhesive makes gummy metals such as aluminum, stainless steels, copper and tantalum much easier to cut for industrial applications. [Credit: Purdue University/Erin Easterling]

The researchers previously showed that marking the metal surface to be machined with ink or an adhesive dramatically reduced the force of cutting, leaving a clean cut in seconds.

One well-known way to make the gummy metal brittle is by coating it with a suitable liquid metal, such as gallium in the case of aluminum. Liquid metals like these, however, tend to work too well; diffusing through the surface and causing the whole metal to crumble into a powder.

"This makes the metal being machined unusable," said Srinivasan Chandrasekar, Purdue professor of industrial engineering.

Attempts using other types of applied media met with limited success and tended to be either toxic or result in tears and cracks on the machined surface. The researchers then began to explore other benign chemical media that would cut cleaner.

VIDEO: Everyday permanent markers, glue sticks, packing tape, and common alcohols may offer a surprisingly low-tech solution to a long-standing nuisance in the manufacturing industry: Making soft and ductile, or so-called "gummy" metals, easier to cut. [Credit: Purdue University]

Eventually, they found that marking with ink or attaching any adhesive on the metal's surface dramatically reduced the force of cutting without the whole metal falling apart, leaving a clean cut in seconds. The quality of the machined surface also greatly improved.

Then the team started asking why, and they found an answer.

"Gummy metals characteristically deform in a very wiggly manner," said Chandrasekar back in 2018. "This wiggly flow involves significant energy consumption, which means that these metals require more force to machine than even some hard metals. We needed to find a way to suppress this wiggly flow."

Getting rid of the wiggles means that the metal tends to act more like a brittle ceramic or glass in the spot where it needs to be cut. Using a thin coating of ink or an adhesive did the trick. [Editor's Note: Please watch the video. There is a section in it -- from 1 min. 30 sec. on -- that demonstrates this.]

Purdue researchers have discovered a simple solution for cutting soft gummy metals (left) -- which tend to "bunch up" or "wriggle" when cut -- just as cleanly and easily as hard metals (right). [Credit: Purdue University image/Anirudh Udupa]

In a 2019 update, the researchers used common alcohols on an aluminum surface and were able to cut the metal more easily, with at least 50% less force, and produce a smoother end surface with fewer cracks and tears compared with aluminum without the alcohol treatment.

Overall, they determined, each metal system requires a specific designer agent (the name for a variety of chemicals used in metals processing), since alcohols do not interact with other metals in the same way as they do with aluminum.

Now, the Purdue team is working on how these films and designer agents produce the effect.

"We have found that you only need the organic film from the markers or glue to be one molecule thick for it to work," said Chandrasekar in his latest update. "This ultra-thin film helps achieve smoother, cleaner, and faster cuts than current machining processes. It also reduces the cutting forces and energy, and improves the outcomes for manufacturing across industries such as biomedical, energy, defense, and aerospace."

The latest research was published in Science Advances in Dec. 2020. The study involves a collaboration between researchers at Purdue, Osaka University (Japan), and the Indian Institute of Science (India). The research is supported by the National Science Foundation and U.S. Department of Energy.

The researchers found, using organic monolayer films created by molecular self-assembly, that the molecule chain length and its adsorption to the metal surface are key to realizing these improvements. By using the "right" organic molecules, the metal is locally embrittled -- resulting in improved machining.

"We are also learning through our discovery more about how environmental factors influence failure of metals," said Anirudh Udupa, a lead author on the study and a researcher in Purdue's School of Industrial Engineering. "As we decipher how the organic molecular films improve the machinability of these metals, the better also is our understanding of common environment-assisted failures in metals, such as stress-corrosion cracking, hydrogen embrittlement, and liquid metal embrittlement."

VIDEO: Improving metal cutting with organic monolayers. [Credit: Purdue Univeristy]

The researchers are looking for partners to continue developing their technology. For more information on licensing and other opportunities, contact Purdue's Office of Technology Commercialization (OTC) at otcip@prf.org and mention track code 2019-CHAN-68634.

Source: Purdue University

Published June 2021

Rate this article

View our terms of use and privacy policy